Factory wholesale Metal Lath For Concrete - Galvanized Plain Woven Wire Mesh Stainless Steel Crimped Wire Mesh – Shengli

Factory wholesale Metal Lath For Concrete - Galvanized Plain Woven Wire Mesh Stainless Steel Crimped Wire Mesh – Shengli Detail:

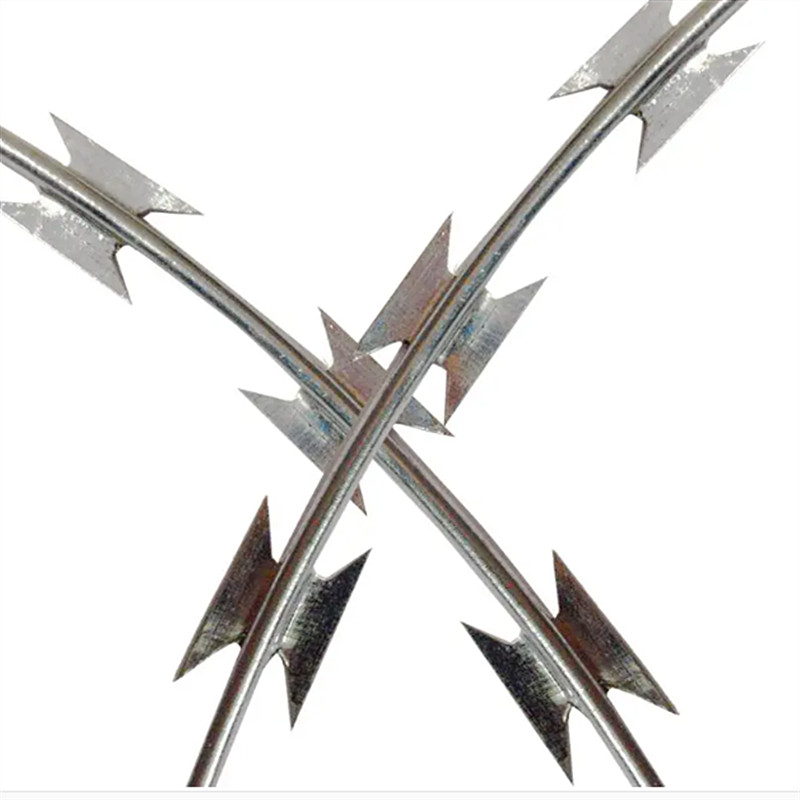

Crimped screen mesh For all of mining, aggregate, asphalt mixing and road construction industries, every cent saved from high-quality production, fast parts changes and a longer part wear life will be eventually converted into hard profits and real cost reduction of companies.

Crrimped screen mesh As the most important part of vibrating screens, a set of high-quality wire cloth with high accuracy, long wear life and high anti-impact is the foundation of production quality assurance in all industries above.

Heavy duty Crimped wire mesh are the most widely used screens in the aggregate and mining industries,due to their high screening area,precision and price ratio.

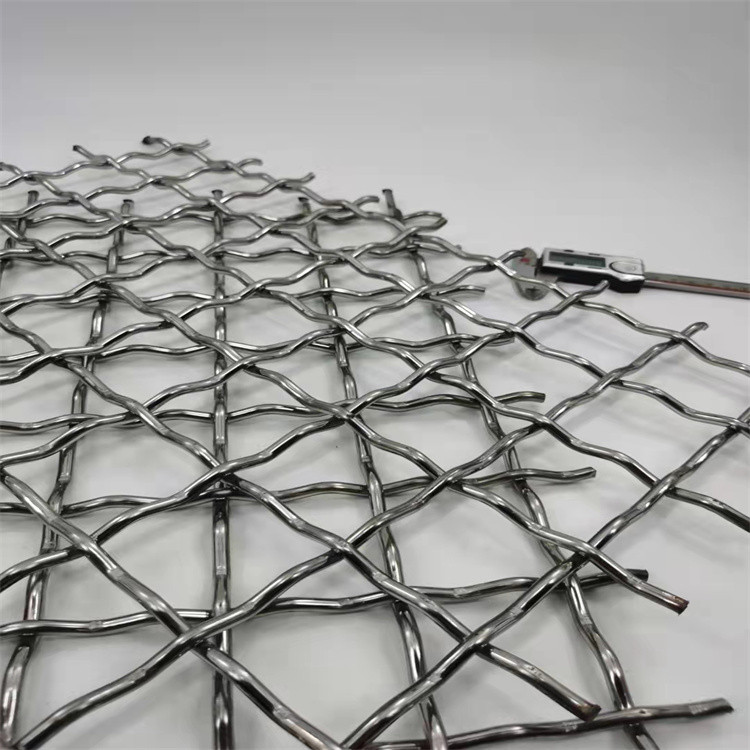

The Crimped wire mesh (mining screen wire mesh,square wire mesh) are manufactured in different geometries (square or slotted meshes) and different weaving styles (double crimped,flat mesh,etc.).

| Name | Stainless steel crimped woven wire mesh /Electro galvanized Iron crimped wire mesh |

| High carbon steel: | 65Mn,45#,50#,55#, 304 and Q195 |

| Wire diameter | 0.8mm-12.7mm,Our finished wire is inspected by third party SGS,Tolerance+_0.03mm. |

| Aperture/Opening | 2mm to 100mm,tolerance +-3% |

| Features: | 1.No tearing and abrasion 2.Placed above rubber beads to avoid metal to metal contact 3.Corrosion resistance 4. High temperature resistance |

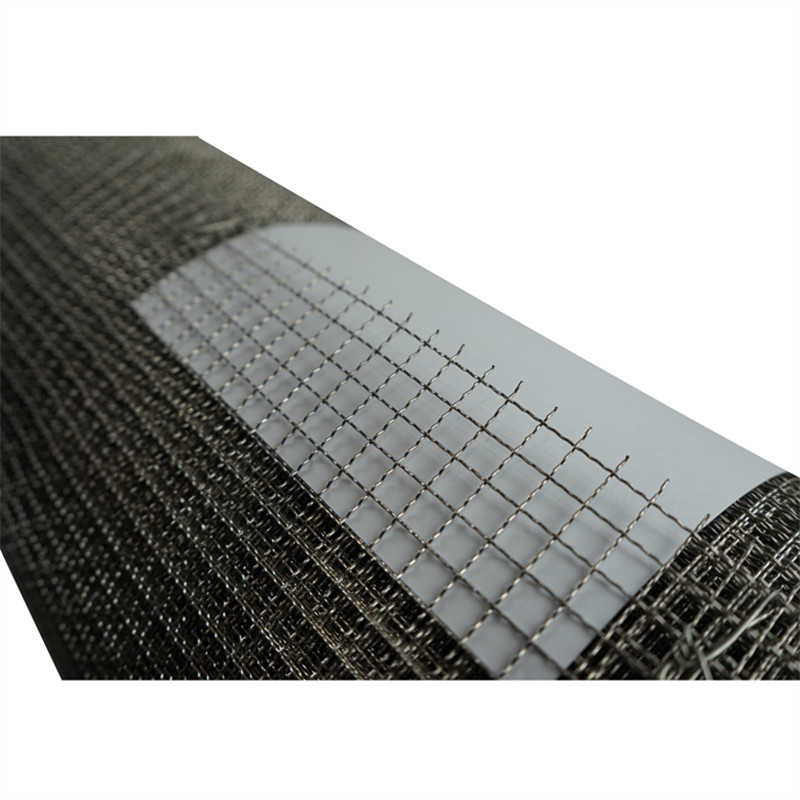

Packing

Piece 1mt 1.2mt 1.5mt 2mt etc. width

2mt 2.5mt 4mt length etc.

Then on the export pallet

Roll

1 1.2 1.5mt etc. 10 15mt 20mt etc. roll ,water-proof packing

Then on the export pallet or wooden case etc.

Packing can be customized .

Product detail pictures:

Related Product Guide:

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and advancement, we will build a prosperous future with each other with your esteemed firm for Factory wholesale Metal Lath For Concrete - Galvanized Plain Woven Wire Mesh Stainless Steel Crimped Wire Mesh – Shengli , The product will supply to all over the world, such as: Greece, Irish, Malta, We now have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we've been looking forward to even greater cooperation with overseas customers based on mutual benefits. You should feel free to contact us for more details.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!

HOT-SALE PRODUCT

Quality First, Safety Guaranteed